Iintlobo ezininzi zokomisa umkhenkce

Isishwankathelo seMinifold Frize Dryers

Isixhobo esomisa umkhenkce esiphindaphindeneyo sisoloko sisetyenziswa njengesixhobo sokungena ekomisweni komkhenkce.Abaphandi abafuna isithako esisebenzayo soxubo-mayeza okanye ukusetyenzwa kwamaqhezu e-HPLC bahlala besebenzisa isomisi esikhenkcezileyo esiphindaphindeneyo ngexesha lamanyathelo abo okuqala elebhu.Isigqibo sokuthenga olu hlobo lokomisa umkhenkce ngokuqhelekileyo lusekwe kwiikhrayitheriya ezibandakanya, kodwa azikhawulelwanga koku:

1. -Inani labasebenzisi kwilebhu lidla ngokuba phezulu kwaye inani lemveliso abayenzayo lincinci

2. -Amanani amakhulu eesampuli ezincinci zomntu ngamnye

3. Uhlahlo lwabiwo-mali lwezixhobo ezincinci

4. Uhlobo lwebhanki yeseli yeziko

5. Ukukhenkcisa imveliso eyomisiweyo ukuba ingasetyenziselwa urhwebo kweli nqanaba

6. Uphando lwakwangoko

7. Ukulungiswa kwemveliso eyimfuneko encinci

Nangona amanani amaninzi eenkqubo ezininzi zithengwa kwaye ziwufanelekele umsebenzi okhoyo, kubalulekile ukuqonda ukuba ukusebenzisa uhlobo oluninzi lwesomisi esikhenkcezayo kunemida ebalulekileyo malunga nenkqubo yomkhenkce.Ekugqibeleni umqhubi akanalo ulawulo lwenkqubo yokomisa umkhenkce, njengoko bebeya kwenza kwitreyi ebiza kakhulu okanye entsonkothileyo okanye isisomisi sohlobo lweshelufu.Nangona kunjalo, kukho amanyathelo anokuthi athathwe ukwenza impumelelo enkulu kwisixhobo esomisa umkhenkce esiphindaphindeneyo xa eso sixhobo sisetyenziswa.Eli nqaku liza kuchaza iinkqubo ezininzi ezisisiseko, ukulinganiselwa kwazo kunye namandla kunye nendlela yokunciphisa ezinye zeengxaki ezinokuthi zenzeke ngexesha lokumisa umkhenkce.

Ukuqonda aMalungu e-Manifold Freeze Dryer

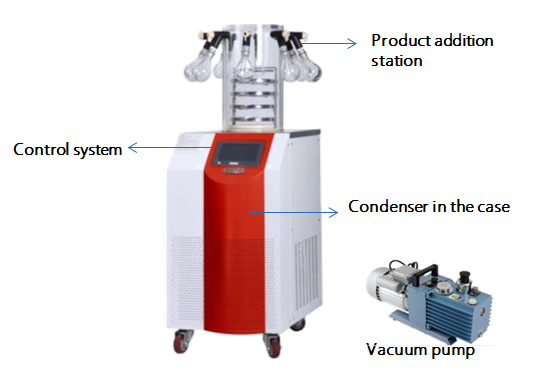

Njengazo zonke izomisi zomkhenkce ezomisa ngeendlela ezininzi zineenxalenye ezi-4 ezisisiseko.Zezi:

· Isikhululo sokongeza imveliso

· Icondenser

· Vacuum

· Inkqubo yokulawula

Product Addition Station

Isikhululo sokongeza imveliso sisiqwenga sesixhobo esazisa imveliso kwisikomisi esikhenkcezayo.Kwimeko yesixokelelwano esininzi izikhongozeli zemveliso zidla ngokuba ziiflaski.Imveliso ifakwa kwi-flask kwaye idla ngokuba ngumkhenkce kwibhafu yobushushu obuphantsi okanye kwisikhenkcisi.Siza kuxoxa ngokhetho lokukhenkceza ngobunzulu ngakumbi kamva kweli nqaku letekhnoloji.

ICondenser

I-condenser phantse kuzo zonke izomisi zomkhenkce zangoku yindawo efrijiweyo esebenza ukuqhuba inkqubo yokuthomalalisa izinto ngokudala

indawo yoxinzelelo oluphantsi kwindawo yokomisa.I-condenser iphinda isebenze ekubanjeni ukufuma / i-solvents kwaye ngaloo ndlela ibathintele ukuba baye kwimpompo yokucoca.Uninzi lwezomisi zomkhenkce zibonelelwa "kwinqanaba elinye"

(i-compressor enye), "izigaba ezimbini" (ii-compressors ezimbini) okanye "iinqanaba ezimbini ezidibeneyo" (iicompressors ezimbini ezinomxube okhethekileyo wegesi).Amazinga obushushu asezantsi kakhulu - 48C (kwiyunithi yenqanaba elinye) ukuya -85C (inkqubo yamaqonga amabini) ayiqhelekanga.Ezinye iinkqubo ezixutyiweyo zinokufikelela kumaqondo obushushu asezantsi, afana ne -105C.Kubalulekile ukuqonda ukuba uxinzelelo lomphunga phezu komkhenkce ayilogophe lomgca.Njengoko amaqondo obushushu ehla kwaye ehla umthetho wokuncipha kwembuyekezo uyasebenza.

IVacuum yeNkqubo kunye nePump yeVacuum

Uxinzelelo lomphunga phezu komkhenkce kwi-48C ilingana ne-37.8 mT.Kwi-85C yi-0.15 mT eguqulela kumahluko malunga ne-37.65

mT.Uyabona nangona kunjalo ukuba ngaphantsi kwe -85C iqondo lokushisa eliphantsi lidala kuphela ukuhla okuncinci okunyukayo kuxinzelelo -kwishumi kunye nekhulu le-milliTorr.Inene, uninzi loxinzelelo lomphunga phezu kweetafile zomkhenkce ezipapashiweyo zimisa malunga no -80C kuba kumaqondo obushushu asezantsi umahluko woxinzelelo awubalulekanga.

Impompo yokufunxa uninzi lwezomisi zokukhenkceza zininzi zizigaba ezibini ezijikelezayo zeoyile etywiniweyo yempompo yokufunxa.Iimpompo zokufunxa injongo yodwa ngexesha lenkqubo yokumisa umkhenkce kukususa umphunga ongaguqukiyo (initrogen, ioksijini, ikharbon diokside et al) kumkhenkce isomisi.Ngokususa iirhasi ezingaguquguqukiyo kwisixokelelwano sempompo yokufunxa ngokuyimfuneko inceda ekudaleni imeko-bume ye-sublimation (umkhenkce ube ngumphunga ngaphandle kokudlula kwinqanaba lolwelo)

ukuba kwenzeke.Ngenxa yokuba zonke izomisi zomkhenkce zinokuvuza (ukuvuza okuqinisekileyo-ukuphuma kwintsimbi engatyiwayo (ewe kusenokuphuma), iigaskets, ii-acrylics et al kunye ne-real-pinhole evuzayo yokuvuza kolungelelwaniso olwahlukeneyo kunye neendawo ngaphakathi kwinkqubo, efana netyhubhu yokufunxa ikhonkco phakathi. Icondenser kunye nempompo yokufunxa) impompo yokufunxa iqhutywa ngokuqhubekayo kuwo wonke umjikelo womkhenkce wokumisa.Ngokwethiyori UKUBA isomisi esikhenkcezayo besivuza ngokupheleleyo kwaye simahla, nje ukuba impompo yokufunxa yenze ukutsalwa kwayo phantsi ibinokuvalwa kwaye ingaphinde isetyenziswe kude kube sekupheleni kokubaleka.Kubomi benene oku akunakwenzeka.

Inkqubo yoLawulo

Inkqubo yolawulo yesomisi esikhenkcezayo iya ibaluleke kakhulu ekwahlulweni kwesinye isixhobo sokumisa ukuya kwesinye.Ubungakanani bokuzenzekelayo kunye nobuhlobo bomsebenzisi bunokwahluka kakhulu ukusuka kumatshini omnye ukuya komnye.Nokuba yeyiphi na i-brand, kuyacetyiswa ukuba i-automatic on and automatic off iyinxalenye yesakhono somlawuli.Kwiilabhoratri apho izomisi ezininzi zisetyenziswa kakhulu, ukomiswa komkhenkce kuyindlela yokufikelela esiphelweni kunye nenye nje inkqubo kuluhlu olude lweenkqubo ekufuneka abantu bazisebenzise ukufezekisa iinjongo zabo.Ayinguye wonke umntu oyingcali yokomisa umkhenkce.Ukuba nemisebenzi ezenzekelayo yokuvula kunye nokucima kunceda ukuqinisekisa ukuba ulandelelwano olufanelekileyo lokuqalisa kunye nokuvala-phantsi lusetyenziselwa ukubonelela ukhuseleko lwenkqubo kunye nokuphila ixesha elide.

Ixesha lokuposa: Jan-21-2022